Our Process

The Process

Locally Sourced Wheat

Local farmers supply our 1 million tonnes of feed grade wheat, making us the biggest wheat buyer in the UK

Our location in the heart of the UK’s wheat growing belt, which is one of the highest yielding in the world, offers us easy access to around 1 million tonnes of feed-wheat we will need annually. We are committed to sourcing our wheat from local farmers wherever possible.

We use ‘feed’ grade wheat which is widely grown in the UK and is most commonly used to feed animals. This is different to ‘milling’ wheat which is used in bread making and other core food products. This lower grade feed wheat is ideal for fermentation due to its high starch content. 60% of the wheat we process will be used to produce the bioethanol. The remaining 40% is protein and that will be converted into animal feed. This type of wheat is widely grown in the local areas around the Vivergo plant.

Our Plant

At full production, we will be one of the largest bioethanol producers in Europe, producing up to 420 million litres every year

Our plant covers an area the size of 12 World Cup football pitches and can produce the amount of bioethanol equivalent to 1 billion bottles of spirits every single year.

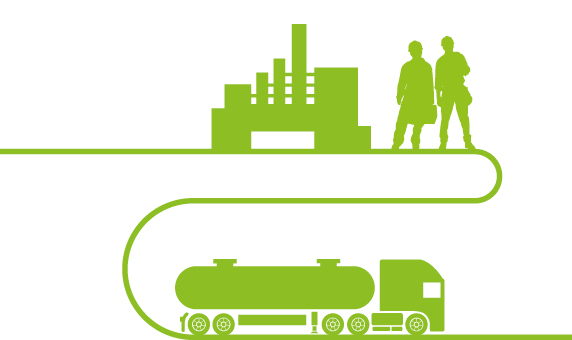

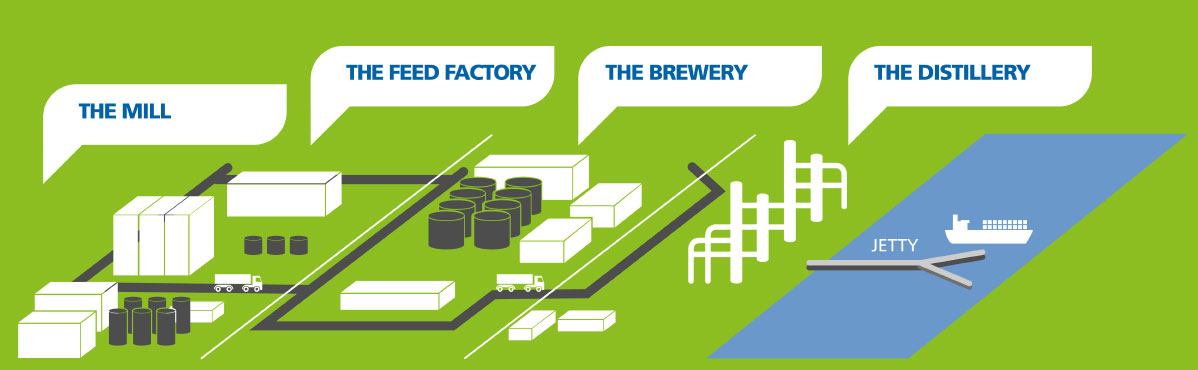

At full production our world-class biorefinery, based at Saltend near Hull, uses around 1 million tonnes of feed-grade wheat to produce up to 420 million litres of bioethanol and 400,000 tonnes of animal feed per year. This will make us the largest bioethanol producer in the UK and one of the biggest in Europe. We will also be the largest wheat tip in the UK and the biggest single-source supplier of animal feed. We definitely don’t do things by halves! At full production, our plant will run 24-hours a day, seven days a week. The whole process begins with locally sourced feed wheat, which is brought to our site by truck. In simple terms, our process is comprised of four key stages – The Mill, The Feed Factory, The Brewery and The Distillery. Read on to discover what happens once the wheat arrives on site…

The Mill

Wheat is made up of starch, protein and fibre. At Vivergo Fuels we use the starch to produce the bioethanol and the protein and fibre to make our animal feeds.

The process will start when the wheat arrives at the site. The wheat grains will be tested for quality and ‘tipped’ into one of our six silos, each of which can hold up to 1,500 tonnes of grain. We refer to the wheat milling and storage area of the site as ‘The Mill’, because it works in the same way as a traditional flour mill. Once the wheat has been milled into flour, it will be mixed with water to form a slurry that is then ‘cooked’ with steam. At this point the product will look a lot like thick porridge! We will then add enzymes to thin the mixture and help convert the starch into sugar before brewing.

The Feed Factory

The proteins and fibre will arrive from distillation and will be squeezed to remove most of the water. At this stage the solid product is still relatively moist. We will then transfer it to our three dryers (think tumble dryer on a massive scale) so that it can be dried and pelletised to form the majority of our animal feed product – which is similar to the food pellets you buy at a petting zoo. Some of the solid product is deliberately not sent through the dryers so that it can be sold in a moist form or as a syrup feed.

The animal feed products will be stored in a large warehouse before being delivered to farms across the UK via truck.

The Brewery

The porridge-like product then moves onto ‘The Brewery’, which is comprised of eight fermentation tanks and a beerwell. Here we will follow a similar process to a conventional brewery – but on an even larger scale!

We will start the brewing phase by adding yeast to the porridge-like product to convert the sugars from wheat starch to alcohol. At the end of each fermentation cycle we are left with a ‘beer’, with an alcohol concentration of around 12%. At this point, the protein and fibre from the remains is suspended in the beer solution. At the end of the brewing process the beer is transferred to the beerwell in preparation for distillation.

The Distillery

In the first stage of distillation we will separate the alcohol from the protein and fibre. In the second stage we will concentrate the alcohol to 96% and then further dry it to 99.7% alcohol. At this point it then becomes our bioethanol product and is sent to storage. It will then be transferred to our jetty for loading onto a ship. It will then be transported to refineries around the UK or into mainland Europe where it is blended with regular petrol for use in conventional car engines. Our process is very efficient, with virtually no waste.

Bioethanol

We will be one of the largest bioethanol producers in Europe, producing up to 420 million litres every year

Bioethanol is a renewable energy made from carbohydrates in plants – at Vivergo Fuels, we use locally sourced feed wheat which is a very sustainable source.

The UK is committed to meeting the EU wide 10% renewable energy in transport target, via the Renewable Transport Fuel Obligation (RTFO) and sustainable biofuels will be the main ‘vehicle’ for achieving this target. In February 2021, the UK Government announced that E10 petrol – a cleaner, greener fuel, will be introduced at UK petrol forecourts up and down the country from September 2021.

E10 contains up to 10% bioethanol and will cut transport emissions, reducing drivers’ environmental impact of every journey taken. As one of the largest bioethanol producers in Europe and the biggest in the UK, Vivergo’s production capacity contributes to a more diverse energy mix, and helping to tackle energy security and climate change both here and across the world.

Animal Feed

Our animal feed provides the protein required for around 20% of the UK's dairy herd.

We will produce up to 400,000 tonnes of animal feed each year, making us the UK's largest single-source supplier.

The local feed wheat Vivergo Fuels uses, was previously used for animal feed products but much of it was exported to European and international markets.

Our process will take in around 1 million tonnes of this wheat, transforming it into up to 400,000 tonnes of animal feed.

The scale of the Vivergo Fuels plant means that we will play an important role in UK agriculture and we are committed to supporting local farmers, as a key part of that.